Number of Placement Heads | 4(high-accuracy) |

Number of IC Trays | 48 |

Number of Feeders | 50/44(subject to 8mm feeder) |

Positioning Accuracy | 0.01mm |

Repeated Mounting Accuracy | 0.05mm |

Mounting speed range of resistance | 5000-8000Pcs/h capacitance components |

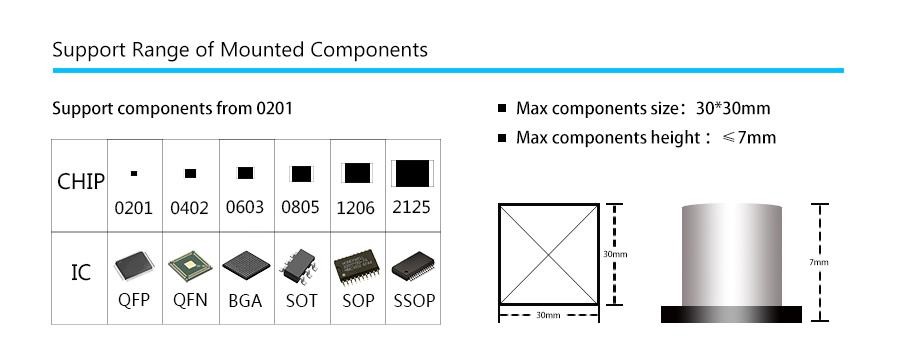

Applicable Components | resistor,capacitor,chip,lamp bead 0201-30*30mm etc. |

Supported Maximum Area of PCB | 50*50mm-(50F)350*190mm /(44F)350*260mm |

Feeders | electric feeder, pneumatic feeder,vibrating feeder, IC tray etc. |

Recognition Devices | mark camera x1,fast recognition camera x4, high-precision camera x1 |

Maximum Height of Applicable Components | ≤7mm |

PCB Convey Mode | three-stage entry,automatic connection from left to right,

automatic PCB positioning |

Mark Positioning | manual / automatic |

Programming Method | automatic programming after manually importing files of PCB

coordinates |

Control System | HuaweiGuochuang control system |

Maximum Step Length of XY Axis | 629mm*679mm |

Tracks of XY Axis | linear motion guide + Screw driver |

Motion Mode of XY Axis | intelligent linkage of acceleration and deceleration of curve and

line, integrated linear interpolation algorithm. |

Control Computer | industrial control computer with Intel high-performance processor |

Adjusting Method of Tracks | electric |

Range of Nozzle Buffer | 4.5mm |

Maximum Step Length of Z Axis | 20mm |

Range of Angle for Components | ±180° |

Motor | AC Servo Motor series |

Driver | high-speed DSP driver |

Air Supply Requirements | oil water filter,≥ 50L,dust filter and air pressure stabilizer etc. |

Vacuum Supply of Nozzle | vacuum generator integrating the high-speed vacuum burst function |

Range of Air Supply Pressure | 0.5-0.7Mpa |

OS | Independent research and development SMT intelligent OS based on

Windows |

PCB requires | 3-5mm process edge in automatic mode |

Vision Display | 17-inch industrial control display |

Cable | durable flexible cable(10 million times) |

Power Supply | 220V 50/60Hz |

Average Power | 600W |

Machine Dimensions | desk machine 1140*900*900mm

vertical machine 900*1140*1340mm |

Weight | (desk machine)210kg (vertical machine)280kg |

,

,